I-liquid nitrogen cooling systems isetshenziswa kabanzi embonini ye-semiconductor & chip, okuhlanganisa inqubo,

- Ubuchwepheshe be-Molecular Beam Epitaxy (MBE)

- Ukuhlolwa kwe-chip ngemva kwephakheji ye-COB

Imikhiqizo Ehlobene

I-MOLECULAR BEAM EPITAXY

Ubuchwepheshe be-Molecular Beam Epitaxy (MBE) bathuthukiswa ngeminyaka yawo-1950 ukuze kulungiswe izinto zefilimu ezacile ze-semiconductor kusetshenziswa ubuchwepheshe be-vacuum evaporation. Ngokuthuthukiswa kobuchwepheshe be-vacuum obuphezulu kakhulu, ukusetshenziswa kobuchwepheshe kuye kwanwetshwa emkhakheni wesayensi ye-semiconductor.

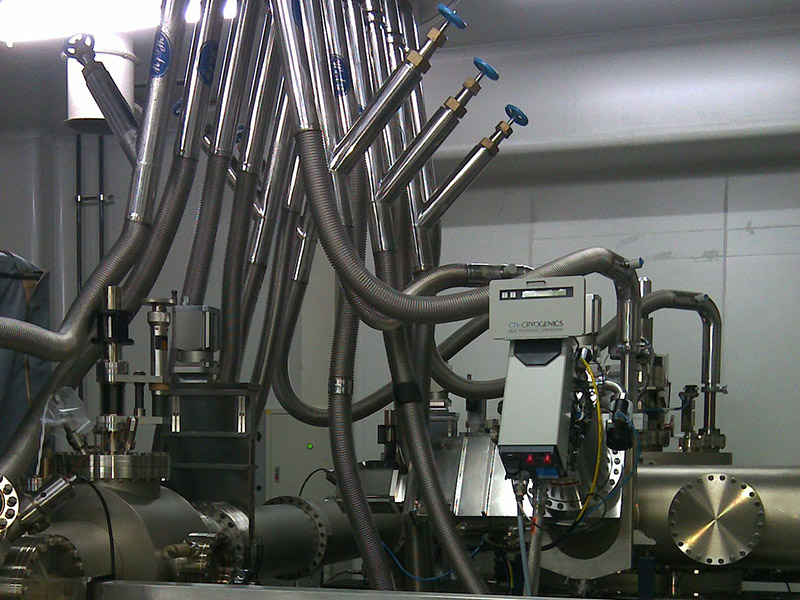

I-HL isibonile isidingo se-MBE liquid nitrogen cooling system, ihlele umgogodla wobuchwepheshe ukuze kuthuthukiswe ngempumelelo uhlelo olukhethekile lwe-MBE liquid nitrogen cooing lobuchwepheshe be-MBE kanye nesethi ephelele yesistimu yamapayipi e-vacuum insulated, esetshenziswe kumabhizinisi amaningi, amanyuvesi kanye nezikhungo zocwaningo.

Izinkinga ezijwayelekile ze-semiconductor & chip industry zihlanganisa,

- Ukucindezela Kwe-Nitrogen Ewuketshezi Kuzisetshenziswa Zetheminali (MBE). Vimbela Ukugcwala Kwengcindezi Ezisetshenziswa Zetheminali Elimazayo (MBE).

- I-Multiple Cryogenic Liquid Inlet kanye ne-Outlet Controls

- Izinga Lokushisa Le-Nitrogen Liquid Into Eyisisetshenziswa Setheminali

- Inani Elizwakalayo Lokukhishwa Kwegesi Ye-Cryogenic

- (Ngokuzenzakalelayo) Ukushintsha Imigqa Eyinhloko Negatsha

- Ukulungiswa Kwengcindezi (Ukunciphisa) Nokuzinza kwe-VIP

- Ukuhlanza Ukungcola Okungaba Khona kanye Nezinsalela Zeqhwa Ethangini

- Isikhathi Sokugcwalisa Isisetshenziswa Soketshezi Lwetheminali

- I-Pipeline Precooling

- I-Liquid Resistance ku-VIP System

- Lawula Ukulahleka Kwe-nitrogen Ewuketshezi Phakathi Nesevisi Eyekiwe Yohlelo

Ipayipi Lepayipi Le-HL's Vacuum Insulated (VIP) yakhelwe ku-ASME B31.3 Ikhodi Yokucindezela Ipayipi njengendlela evamile. Ulwazi lobunjiniyela kanye nekhono lokulawula ikhwalithi ukuze kuqinisekiswe ukusebenza kahle kanye nokusebenza kahle kwezindleko zemboni yekhasimende.

IZIXAZULULO

I-HL Cryogenic Equipment ihlinzeka amakhasimende nge-Vacuum Insulated Piping System ukuze ahlangabezane nezidingo nezimo zemboni ye-semiconductor & chip:

1.Isistimu Yokulawula Ikhwalithi: ASME B31.3 Ikhodi Yokubhobhoza Ngokucindezela.

2.Isihlukanisi Sesigaba Esikhethekile Esine-Multiple Cryogenic Liquid Inlet kanye ne-Outlet esisebenza ngokuzenzakalelayo sokulawula sihlangabezana nemfuneko yokukhishwa kwegesi, i-nitrogen ewuketshezi egaywe kabusha kanye nezinga lokushisa le-nitrogen ewuketshezi.

3.Idizayini yokukhipha umoya eyanele futhi efika ngesikhathi iqinisekisa ukuthi okokusebenza kwetheminali kuhlala kusebenza ngaphakathi kwevelu yokucindezela eklanyelwe.

4.I-Gas-liquid Barrier ibekwe epayipini eliqondile elingu-VI ekugcineni kwepayipi le-VI. I-Gas-liquid Barrier isebenzisa umgomo wokuvala igesi ukuvimba ukushisa kusukela ekupheleni kwepayipi le-VI ukuya ku-VI Piping, futhi yehlise ngempumelelo ukulahlekelwa yi-nitrogen ewuketshezi phakathi nesevisi engaqhubeki nesikhashana yohlelo.

5.VI Amapayipi Alawulwa Uchungechunge Lwevacuum Insulated Valve (VIV): Kuhlanganisa Ivacuum Insulated (Pneumatic) Shut-off Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve njll. Izinhlobo ezahlukene ze-VIV zingahlanganiswa ukuze ulawule i-VIP njengoba kudingeka. I-VIV ihlanganiswe ne-VIP prefabrication kumkhiqizi, ngaphandle kokwelashwa kwe-Insulated endaweni. Iyunithi yophawu lwe-VIV ingashintshwa kalula. (I-HL yamukela uhlobo lwe-valve ye-cryogenic olukhethwe amakhasimende, bese yenza ama-vacuum insulated valves nge-HL. Amanye amabhrendi namamodeli wamavalvu angase angakwazi ukwenziwa amavavu avaleleke avale.)

6.Ukuhlanzeka, uma kunezidingo ezengeziwe zokuhlanzeka kwendawo yangaphakathi yeshubhu. Kuphakanyiswa ukuthi amakhasimende akhethe i-BA noma amapayipi ensimbi engagqwali e-EP njengamapayipi angaphakathi e-VIP ukuze kuqhutshekwe nokunciphisa ukuchitheka kwensimbi engagqwali.

7.Vacuum Insulated Filter: Hlanza ukungcola okungenzeka kanye nezinsalela zeqhwa ethangini.

8.Ngemva kwezinsuku ezimbalwa noma ukuvala shaqa isikhathi eside noma ukulungiswa, kudingekile kakhulu ukupholisa kuqala i-VI Piping kanye nemishini yokugcina ngaphambi kokuba kufakwe uketshezi lwe-cryogenic, ukuze ugweme i-ice slag ngemva kokuba uketshezi lwe-cryogenic lungene ngokuqondile ku-VI Piping kanye nemishini yokugcina. Umsebenzi wokupholisa kuqala kufanele ucatshangelwe ekuklanyweni. Ihlinzeka ngokuvikeleka okungcono kwemishini yokugcina kanye nemishini yokusekela ye-VI Piping njengama-valve.

9.Isudi yakho kokubili i-Dynamic Vacuum Insulated (Flexible) System yamapayipi.

10.Uhlelo Lwepayipi Lwe-Dynamic Vacuum Insulated (Flexible): Luhlanganisa amapayipi aguquguqukayo we-VI kanye/noma i-VI Pipe, ama-Jumper Hoses, i-Vacuum Insulated Valve System, Izihlukanisi zeSigaba kanye neSistimu Yephampu Yevacuum Anamandla (okuhlanganisa amaphampu evacuum, amavalvu e-solenoid kanye nokunye. Ubude be-single VI Flexible Hose bungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi.

11.Izinhlobo Zokuxhuma Ezihlukahlukene: Uhlobo Lwe-Vacuum Bayonet Connection (VBC) kanye Noxhumano Olushiselwe lungakhethwa. Uhlobo lwe-VBC aludingi ukwelashwa kwe-insulated endaweni.