Izinhlelo zokupholisa ze-nitrogen ewuketshezi zisetshenziswa kabanzi embonini ye-semiconductor kanye ne-chip, okuhlanganisa nenqubo,

- Ubuchwepheshe be-Molecular Beam Epitaxy (MBE)

- Ukuhlolwa kwe-chip ngemuva kwephakheji ye-COB

Imikhiqizo Ehlobene

I-EPITAXY YOMGQA WAMAMOLEKULA

Ubuchwepheshe be-Molecular Beam Epitaxy (MBE) basungulwa ngawo-1950 ukuze kulungiswe izinto zefilimu encane ye-semiconductor kusetshenziswa ubuchwepheshe bokuhwamuka kwe-vacuum. Ngokuthuthuka kobuchwepheshe be-vacuum obuphezulu kakhulu, ukusetshenziswa kobuchwepheshe kuye kwandiselwa emkhakheni wesayensi ye-semiconductor.

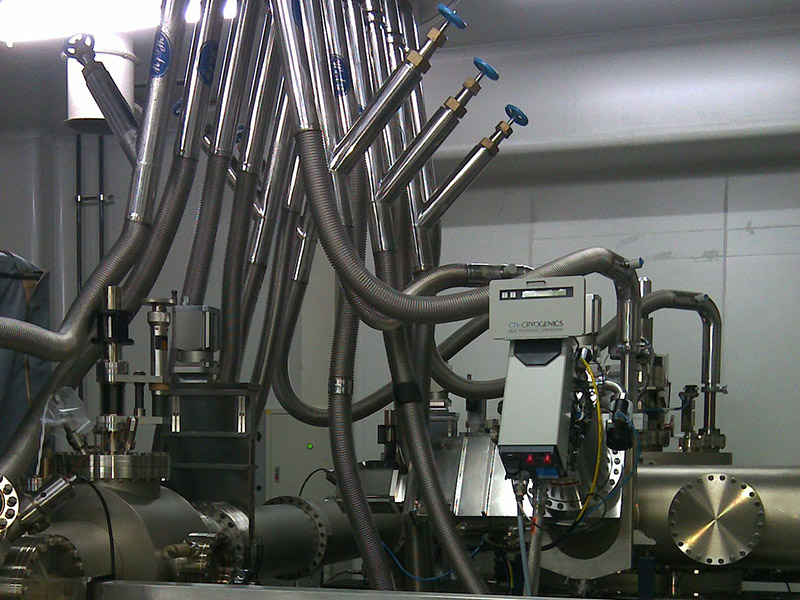

I-HL iqaphele isidingo sohlelo lokupholisa lwe-MBE liquid nitrogen, umgogodla wezobuchwepheshe ohleliwe ukuze kuthuthukiswe ngempumelelo uhlelo olukhethekile lwe-MBE liquid nitrogen cooing lobuchwepheshe be-MBE kanye nesethi ephelele yesistimu yamapayipi afakwe i-vacuum insulation, olusetshenziswe emabhizinisini amaningi, emanyuvesi nasezikhungweni zocwaningo.

Izinkinga ezivamile zemboni ye-semiconductor kanye ne-chip zifaka phakathi,

- Ukucindezela kwe-Liquid Nitrogen ku-Terminal (MBE). Vimbela ukucindezeleka ngokweqile emishinini eyonakalisayo ye-Terminal (MBE).

- Izilawuli Zokungena Nokuphuma Koketshezi Eziningi Ezine-Cryogenic

- Izinga Lokushisa Le-Nitrogen Ewuketshezi Emishinini Yesiphetho

- Inani Elifanele Lokukhishwa Kwegesi E-Cryogenic

- (Okuzenzakalelayo) Ukushintshana Kwemigqa Eyinhloko Neyegatsha

- Ukulungiswa Kokucindezela (Ukunciphisa) kanye Nokuzinza kwe-VIP

- Ukuhlanza Ukungcola Okungenzeka kanye Nensalela Yeqhwa Ethangini

- Isikhathi Sokugcwalisa Semishini Yoketshezi Yesiphetho

- Ukupholisa Amapayipi Ngaphambi Kokuphakelwa

- Ukumelana Noketshezi Kuhlelo lwe-VIP

- Lawula Ukulahlekelwa Yi-Nitrogen Ewuketshezi Ngesikhathi Sokungasebenzi Kwesistimu

Ipayipi Elifakwe I-Vacuum Insulated (VIP) le-HL lakhiwe ngokwekhodi yepayipi lokucindezela i-ASME B31.3 njengendinganiso. Ulwazi lobunjiniyela kanye nekhono lokulawula ikhwalithi ukuqinisekisa ukusebenza kahle kanye nokusebenza kahle kwesitshalo sekhasimende.

IZIXAZULULO

I-HL Cryogenic Equipment inikeza amakhasimende uhlelo lwe-Vacuum Insulated Piping System ukuze kuhlangatshezwane nezidingo nemibandela yemboni ye-semiconductor kanye ne-chip:

1. Uhlelo Lokuphatha Ikhwalithi: Ikhodi Yamapayipi Okucindezela e-ASME B31.3.

2.Isihlukanisi Sesigaba Esikhethekile Esine-Multiple Cryogenic Liquid Inlet kanye ne-Outlet enomsebenzi wokulawula okuzenzakalelayo ihlangabezana nesidingo sokukhishwa kwegesi, i-nitrogen ewuketshezi ephinde yasetshenziswa kanye nokushisa kwe-nitrogen ewuketshezi.

3. Umklamo wokukhipha umoya owanele futhi ofike ngesikhathi uqinisekisa ukuthi imishini yokugcina isebenza ngaphakathi kwenani lokucindezela eliklanywe kahle.

4. I-Gas-liquid Barrier ifakwa epayipini le-VI eliqondile ekugcineni kwepayipi le-VI. I-Gas-liquid Barrier isebenzisa isimiso sokuvala igesi ukuvimba ukushisa kusukela ekugcineni kwepayipi le-VI kuya epayipini le-VI, futhi inciphise ngempumelelo ukulahleka kwe-nitrogen ewuketshezi ngesikhathi senkonzo engaqhubeki nengahleliwe yesistimu.

5. Ipayipi le-VI Elilawulwa yiValve Efakwe Umshini Wokushaja (VIV) Uchungechunge: Kufaka phakathi iValve Efakwe Umshini Wokushaja (i-Pneumatic), iValve Yokuhlola Efakwe Umshini Wokushaja, iValve Yokulawula Efakwe Umshini Wokushaja njll. Izinhlobo ezahlukene ze-VIV zingahlanganiswa ngendlela efanayo ukulawula i-VIP njengoba kudingeka. I-VIV ihlanganiswe ne-VIP prefabrication kumkhiqizi, ngaphandle kokwelashwa okufakwe Umshini Wokushaja endaweni. Iyunithi yokuvala ye-VIV ingashintshwa kalula. (I-HL yamukela uhlobo lwe-valve olubizwa ngokuthi i-cryogenic valve oluqokwe amakhasimende, bese yenza amavalve afakwe umshini wokushaja yi-HL. Amanye amabhrendi namamodeli amavalvu kungenzeka angakwazi ukwenziwa amavalvu afakwe umshini wokushaja.)

6. Ukuhlanzeka, uma kunezidingo ezengeziwe zokuhlanzeka kobuso bepayipi langaphakathi. Kuphakanyiswa ukuthi amakhasimende akhethe amapayipi ensimbi engagqwali e-BA noma e-EP njengamapayipi angaphakathi e-VIP ukuze kuncishiswe ukuchitheka kwensimbi engagqwali.

7. Isihlungi Esifakwe Umshini Wokuhlanza: Hlanza ukungcola okungenzeka kanye nezinsalela zeqhwa ethangini.

8.Ngemva kwezinsuku ezimbalwa noma ukuvalwa noma ukulungiswa okude, kubalulekile kakhulu ukupholisa imishini ye-VI Piping kanye ne-terminal ngaphambi kokufakwa koketshezi olu-cryogenic, ukuze kugwenywe ukuchitheka kweqhwa ngemuva kokungena koketshezi olu-cryogenic ngqo kumishini ye-VI Piping kanye ne-terminal. Umsebenzi wangaphambi kokupholisa kufanele ucatshangelwe ekwakhiweni. Uhlinzeka ngokuvikelwa okungcono kwemishini ye-terminal kanye nemishini yokusekela i-VI Piping efana nama-valve.

9. Ilungele kokubili uhlelo lwamapayipi oluguquguqukayo (oluguquguqukayo) nolunamandla.

10. Uhlelo Lokuphayipha Olune-Dynamic Vacuum Insulated (Flexible): Luqukethe ama-VI Flexible Hoses kanye/noma i-VI Pipe, ama-Jumper Hoses, i-Vacuum Insulated Valve System, ama-Phase Separators kanye ne-Dynamic Vacuum Pump System (kufaka phakathi ama-vacuum pump, ama-solenoid valves kanye nama-vacuum gauges njll.). Ubude be-single VI Flexible Hose bungenziwa ngokwezifiso ngokwezidingo zomsebenzisi.

11. Izinhlobo Ezihlukahlukene Zokuxhuma: Uhlobo Lokuxhuma Nge-Vacuum Bayonet (VBC) kanye Nokuxhuma Okuhlanganisiwe kungakhethwa. Uhlobo lwe-VBC aludingi ukwelashwa okufakwe ngaphakathi.