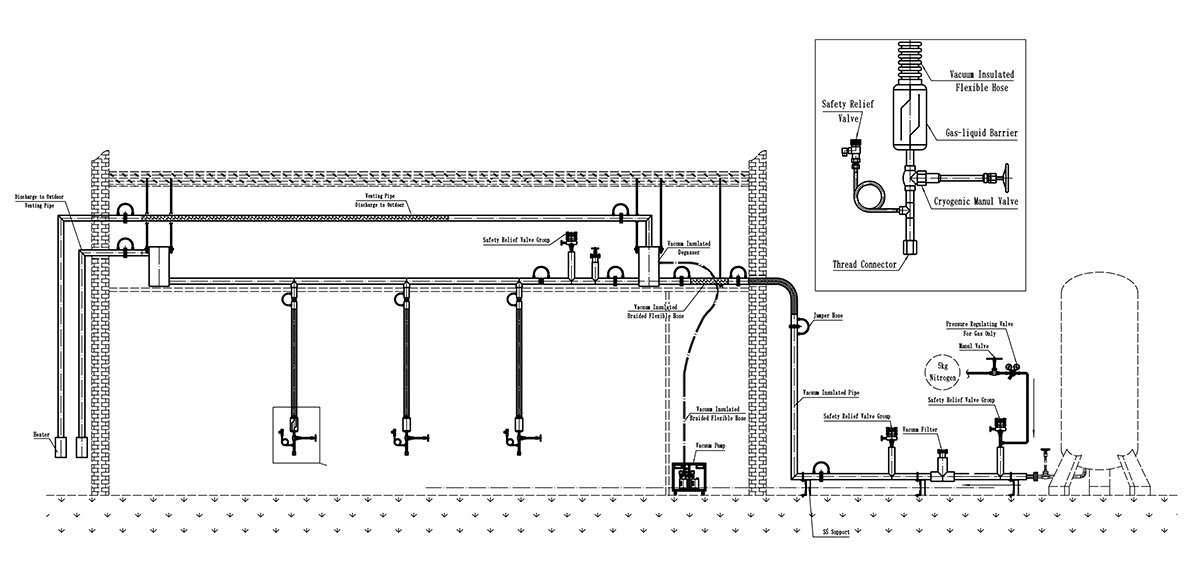

Ukukhiqizwa kanye nokwakhiwa kwe-Vacuum Insulated Piping System yokuhambisa i-nitrogen ewuketshezi kungumthwalo womhlinzeki. Kulo msebenzi, uma umhlinzeki engenazo izimo zokulinganisa endaweni, indlu kufanele idwebe izinkomba zepayipi. Ngemuva kwalokho umhlinzeki uzoklama i-VI Piping System yezimo ze-nitrogen ewuketshezi.

Umhlinzeki kufanele aqedele ukuklama okuphelele kohlelo lwamapayipi ngabaklami abanolwazi ngokuya ngemidwebo, imingcele yemishini, izimo zendawo, izici ze-nitrogen ewuketshezi kanye nezinye izici ezinikezwe ngumceli.

Okuqukethwe komklamo kufaka phakathi uhlobo lwezesekeli zesistimu, ukunqunywa kwezinto kanye nemininingwane yamapayipi angaphakathi nangaphandle, ukwakheka kohlelo lokufaka ukushisa, uhlelo lwesigaba olusetshenziselwe kusengaphambili, ifomu lokuxhuma phakathi kwezingxenye zamapayipi, ibhulakhethi lamapayipi angaphakathi, inombolo nendawo yevalvu yokuvaleka, ukususwa kophawu lwegesi, izidingo zoketshezi oluyi-cryogenic lwemishini yokugcina, njll. Lolu hlelo kufanele luqinisekiswe ngabasebenzi abangochwepheshe bomceli ngaphambi kokukhiqiza.

Okuqukethwe komklamo we-Vacuum Insulated Piping System kubanzi, lapha kuzinhlelo zokusebenza ze-HASS kanye nemishini ye-MBE ezinkingeni ezithile ezivamile, ingxoxo elula.

Ipayipi le-VI

Ithangi lokugcina i-nitrogen ewuketshezi livame ukuba lide kakhulu kunemishini ye-HASS Application noma ye-MBE. Ngenkathi ipayipi elifakwe i-vacuum insulation lingena esakhiweni ngaphakathi, kudingeka ligwenywe ngokufanele ngokwesakhiwo segumbi esakhiweni kanye nendawo yepayipi yasensimini kanye nepayipi lomoya. Ngakho-ke, ukuthutha i-nitrogen ewuketshezi emishinini, okungenani amakhulu amamitha epayipi.

Ngenxa yokuthi i-nitrogen ewuketshezi ecindezelwe ngokwayo iqukethe inani elikhulu legesi, kanye nebanga lokuhamba, ngisho nepayipi le-vacuum adiabatic lizokhiqiza inani elikhulu le-nitrogen enqubweni yokuthutha. Uma i-nitrogen ingakhishwa noma ukukhishwa kwayo kuphansi kakhulu ukuhlangabezana nezidingo, kuzobangela ukumelana negesi futhi kuholele ekugelezeni okubi kwe-nitrogen ewuketshezi, okuholela ekunciphiseni okukhulu kwesilinganiso sokugeleza.

Uma izinga lokugeleza linganele, izinga lokushisa ekamelweni le-nitrogen eliwuketshezi lemishini alikwazi ukulawulwa, okungagcina kuholele ekulimaleni kwemishini noma ikhwalithi yomkhiqizo.

Ngakho-ke, kubalulekile ukubala inani le-nitrogen ewuketshezi esetshenziswa imishini yokugcina (i-HASS Application noma imishini ye-MBE). Ngesikhathi esifanayo, imininingwane yepayipi inqunywa ngokuya ngobude bepayipi kanye nesiqondiso, futhi.

Kusukela ethangini lokugcina i-nitrogen eliwuketshezi, uma ipayipi eliyinhloko lepayipi/ipayipi elifakwe i-vacuum insulation lingu-DN50 (ububanzi bangaphakathi bungu-φ50 mm), ipayipi/ipayipi legatsha lalo le-VI lingu-DN25 (ububanzi bangaphakathi bungu-φ25 mm), kanti ipayipi eliphakathi kwepayipi legatsha kanye nemishini yokugcina lingu-DN15 (ububanzi bangaphakathi bungu-φ15 mm). Ezinye izinto zokufaka uhlelo lwepayipi le-VI, okuhlanganisa i-Phase Separator, i-Degasser, i-Automatic Gas Vent, i-VI/Cryogenic (Pneumatic) Shut-off Valve, i-VI Pneumatic Flow Regulating Valve, i-VI/Cryogenic Check Valve, isihlungi se-VI, i-Safety Relief Valve, uhlelo lokuhlanza, kanye ne-Vacuum Pump njll.

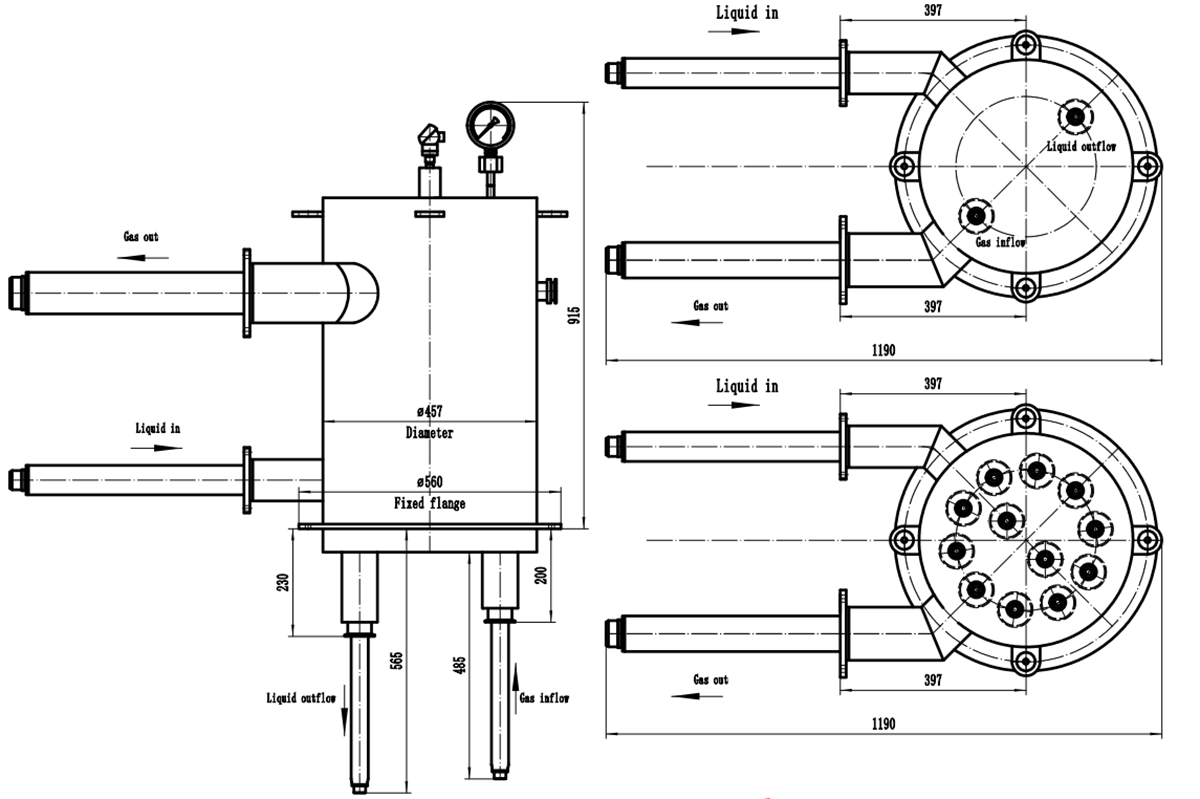

Isihlukanisi Sesigaba Esikhethekile se-MBE

Isihlukanisi ngasinye sesigaba sokucindezela esijwayelekile se-MBE sinomsebenzi olandelayo:

1. Inzwa yezinga loketshezi kanye nohlelo lokulawula izinga loketshezi oluzenzakalelayo, futhi luboniswa ngokushesha ngebhokisi lokulawula likagesi.

2. Umsebenzi wokunciphisa ingcindezi: indawo yokungena yoketshezi yesihlukanisi ifakwe uhlelo olusizayo lwesihlukanisi, oluqinisekisa ingcindezi ye-nitrogen ewuketshezi engu-3-4 bar epayipini eliyinhloko. Uma ungena kwi-Phase Separator, yehlisa ingcindezi kancane kancane ibe yi-≤ 1Bar.

3. Ukulawulwa kokugeleza kokungena koketshezi: uhlelo lokulawula ukubutha luhlelwe ngaphakathi kwe-Phase Separator. Umsebenzi walo ukulungisa ngokuzenzakalelayo inani lokungena koketshezi lapho ukusetshenziswa kwe-nitrogen yoketshezi kwanda noma kwehla. Lokhu kunenzuzo yokunciphisa ukuguquguquka okukhulu kwengcindezi okubangelwa ukungena kwenani elikhulu le-nitrogen yoketshezi lapho i-valve yomoya yokungena ivulwa futhi kuvimbele ukucindezeleka ngokweqile.

4. Umsebenzi we-Buffer, ivolumu esebenzayo ngaphakathi kwesihlukanisi iqinisekisa ukugeleza okuphezulu okusheshayo kwedivayisi.

5. Uhlelo lokuhlanza: ukuhamba komoya kanye nomhwamuko wamanzi kusihlukanisi ngaphambi kokudlula kwe-nitrogen ewuketshezi, kanye nokukhishwa kwe-nitrogen ewuketshezi kusihlukanisi ngemva kokudlula kwe-nitrogen ewuketshezi.

6. Umsebenzi wokusiza ngokuzenzakalelayo ngokucindezela ngokweqile: Imishini, lapho iqala ukudlula ku-nitrogen ewuketshezi noma ngaphansi kwezimo ezikhethekile, iholela ekwandeni kokufakwa kwegesi kwe-nitrogen ewuketshezi, okuholela ekucindezelweni okukhulu ngokushesha kwesistimu yonke. I-Phase Separator yethu ifakwe i-Safety Relief Valve kanye ne-Safety Relief Valve Group, engaqinisekisa kangcono ukuzinza kwengcindezi kusihlukanisi futhi ivimbele imishini ye-MBE ukuthi yonakale ngenxa yokucindezela ngokweqile.

7. Ibhokisi lokulawula likagesi, ukuboniswa kwesikhathi sangempela kwezinga loketshezi kanye nenani lokucindezela, kungabeka izinga loketshezi kusihlukanisi kanye ne-nitrogen ewuketshezi enanini lobudlelwano bokulawula. Ngesikhathi esifanayo. Esimweni esiphuthumayo, ukubhuleka ngesandla kwesihlukanisi segesi evalweni lokulawula uketshezi, ukuze abasebenzi bendawo kanye nemishini baqinisekise ukuphepha.

I-Multi-core Degasser yezinhlelo zokusebenza ze-HASS

Ithangi lokugcina i-nitrogen ewuketshezi yangaphandle liqukethe inani elikhulu le-nitrogen ngoba ligcinwa futhi lithuthwa ngaphansi kwengcindezi. Kulesi simiso, ibanga lokuthuthwa kwepayipi lide, kunezindololwane eziningi kanye nokumelana okukhulu, okuzobangela ukukhiqizwa kwe-nitrogen ewuketshezi ngegesi okungaphelele. Ishubhu elifakwe i-vacuum insulation liyindlela engcono kakhulu yokuthutha i-nitrogen ewuketshezi njengamanje, kodwa ukuvuza kokushisa akunakugwenywa, okuzophinde kuholele ekufakweni kwe-nitrogen ewuketshezi ngegesi okungaphelele. Ngamafuphi, i-nitrogen ewuketshezi iqukethe inani elikhulu le-nitrogen, okuholela ekwakhiweni kokumelana negesi okungaphelele, okuholela ekugelezeni kwe-nitrogen ewuketshezi kungabi bushelelezi.

Imishini yokukhipha ugesi epayipini elivalekile, uma ingekho idivayisi yokukhipha ugesi noma ivolumu yokukhipha enganele, izoholela ekumelaneni negesi. Uma ukumelana negesi sekukhona, amandla okudlulisa i-nitrogen ewuketshezi azoncishiswa kakhulu.

I-Multi-core Degasser eyenzelwe inkampani yethu kuphela ingaqinisekisa ukuthi i-nitrogen ikhishwa epayipini eliyinhloko le-nitrogen eliwuketshezi ngezinga eliphezulu futhi ivimbele ukwakheka kokumelana negesi. Futhi i-Multi-core Degasser inomthamo owanele wangaphakathi, ingadlala indima yethangi lokugcina i-buffer, ingahlangabezana ngempumelelo nezidingo zokugeleza okusheshayo okuphezulu kwepayipi lesisombululo.

Isakhiwo esiyingqayizivele esinelungelo lobunikazi esinezinsika eziningi, amandla okukhipha umoya asebenza kahle kakhulu kunezinye izinhlobo zethu zokuhlukanisa.

Ukuqhubeka nesihloko esandulele, kunezinkinga ezithile okudingeka zicatshangelwe lapho kuklanywa izixazululo ze-Vacuum Insulated Piping System zezinhlelo zokusebenza ze-cryogenic embonini ye-Chip.

Izinhlobo Ezimbili Zohlelo Lokufaka Amapayipi Olufakwe I-Vacuum

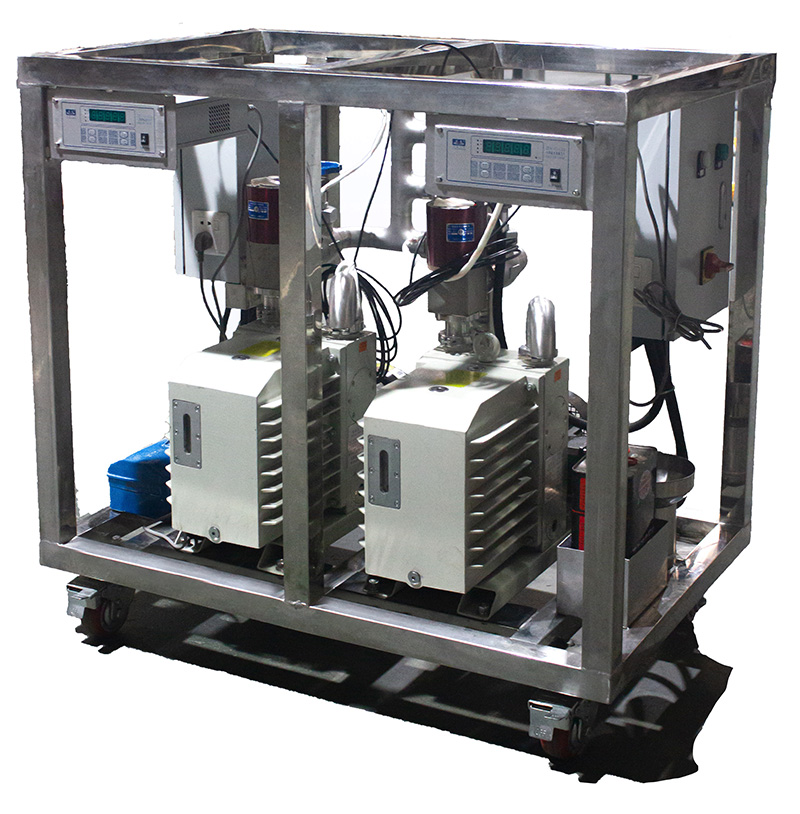

Kunezinhlobo ezimbili zeSistimu Yokupompa Amapayipi E-Vacuum Insulated: Uhlelo lwe-Static VI kanye noHlelo Lokupompa Amapayipi E-Dynamic Vacuum.

Uhlelo lwe-Static VI lusho ukuthi ngemva kokuba ipayipi ngalinye lenziwe efektri, liyahlanzwa nge-vacuum ngezinga elibekiwe le-vacuum kuyunithi yokupompa bese livalwa. Ekufakweni kwensimu bese lisetshenziswa, isikhathi esithile asidingi ukususwa kabusha siye endaweni.

Inzuzo ye-Static VI System izindleko zokulungisa eziphansi. Uma uhlelo lwamapayipi selusebenza, ukulungiswa kuyadingeka eminyakeni eminingana kamuva. Lolu hlelo lwe-vacuum lufanelekela izinhlelo ezingadingi izidingo eziphezulu zokupholisa kanye nezindawo ezivulekile zokulungisa endaweni.

Ububi be-Static VI System ukuthi i-vacuum iyancipha ngokuhamba kwesikhathi. Ngoba zonke izinto zikhipha amagesi amancane ngaso sonke isikhathi, okunqunywa yizakhiwo ezibonakalayo zezinto. Izinto ezisejazini le-VI Pipe zinganciphisa inani legesi elikhishwa yinqubo, kodwa azikwazi ukuhlukaniswa ngokuphelele. Lokhu kuzoholela ekutheni i-vacuum yendawo ye-vacuum evaliwe ingabi manzi, izoba manzi futhi ibe manzi, i-vacuum insulation tube izonciphisa kancane kancane ikhono lokupholisa.

Uhlelo Lokupompa I-Dynamic Vacuum lusho ukuthi ngemva kokuba ipayipi lenziwe futhi lakhiwe, ipayipi liyaqhubeka likhishwa efektri ngokwenqubo yokutholwa kokuvuza, kodwa i-vacuum ayivalwanga ngaphambi kokulethwa. Ngemva kokufakwa kwensimu sekuqediwe, izingqimba ze-vacuum zazo zonke amapayipi kufanele zixhunywe kuyunithi eyodwa noma ngaphezulu ngamapayipi ensimbi engagqwali, futhi iphampu encane ye-vacuum ezinikele kufanele isetshenziswe ukuhlanza amapayipi ensimini. Iphampu ekhethekile ye-vacuum inohlelo oluzenzakalelayo lokuqapha i-vacuum nganoma yisiphi isikhathi, kanye nokuhlanza njengoba kudingeka. Uhlelo lusebenza amahora angama-24 ngosuku.

Ububi be-Dynamic Vacuum Pumping System ukuthi i-vacuum idinga ukugcinwa ngogesi.

Inzuzo ye-Dynamic Vacuum Pumping System ukuthi izinga le-vacuum lizinzile kakhulu. Lisetshenziswa kakhulu ezindaweni zangaphakathi kanye nezidingo zokusebenza kwe-vacuum zamaphrojekthi aphezulu kakhulu.

Uhlelo lwethu Lokupompa I-Vacuum Olunamandla, lonke iphampu ekhethekile ye-vacuum ehlanganisiwe yeselula ukuqinisekisa ukuthi imishini iyavalwa, ukwakheka okulula nokunengqondo ukuqinisekisa umphumela we-vacuum, ikhwalithi yezesekeli ze-vacuum ukuqinisekisa ikhwalithi ye-vacuum.

Kuphrojekthi ye-MBE, ngoba imishini isegumbini elihlanzekile, futhi imishini isebenza isikhathi eside. Iningi lesistimu yamapayipi afakwe i-vacuum insulation lisendaweni evaliwe engqimbeni yegumbi elihlanzekile. Akunakwenzeka ukusebenzisa ukugcinwa kwe-vacuum kwesistimu yamapayipi esikhathini esizayo. Lokhu kuzoba nomthelela omkhulu ekusebenzeni kwesikhathi eside kwesistimu. Ngenxa yalokho, iphrojekthi ye-MBE isebenzisa cishe yonke i-Dynamic Vacuum Pumping System.

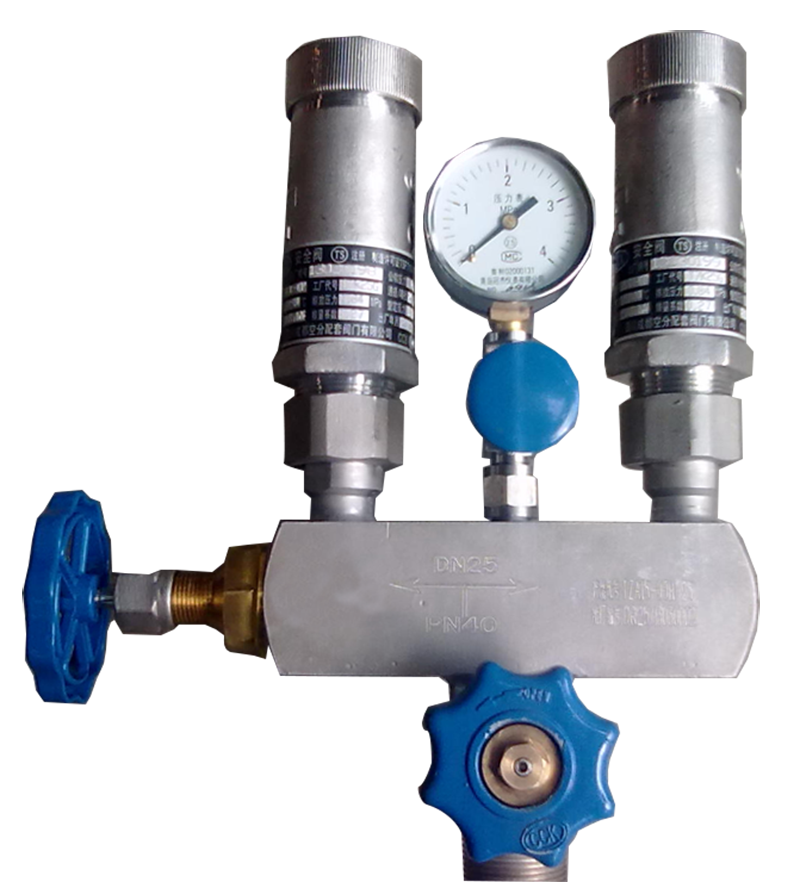

Uhlelo Lokusiza Ukucindezeleka

Uhlelo lokunciphisa ingcindezi lomugqa oyinhloko lusebenzisa i-Safety Relief Valve Group. I-Safety Relief Valve Group isetshenziswa njengohlelo lokuvikela ukuphepha lapho ukucindezela ngokweqile, i-VI Piping ingenakushintshwa ekusetshenzisweni okuvamile

I-Safety Relief Valve iyisici esibalulekile sokuqinisekisa ukuthi uhlelo lwamapayipi ngeke lube nokucindezela ngokweqile, ukusebenza okuphephile, ngakho-ke kubalulekile ekusebenzeni kwamapayipi. Kodwa i-safety valve ngokwemithetho, kumele ithunyelwe ukuze ihlolwe njalo ngonyaka. Uma kusetshenziswa i-safety valve eyodwa futhi enye ilungisiwe, lapho i-safety valve eyodwa isusiwe, enye i-safety valve isesesistimu yamapayipi ukuqinisekisa ukusebenza okuvamile kwepayipi.

I-Safety Relief Valve Group iqukethe ama-DN15 Safety Relief Valve amabili, elilodwa lokusetshenziswa kanye nelinye lokulinda. Ekusebenzeni okuvamile, ama-Safety Relief Valve elilodwa kuphela elixhunywe ne-VI Piping System futhi lisebenza ngokujwayelekile. Amanye ama-Safety Relief Valve anqanyuliwe epayipini elingaphakathi futhi angashintshwa nganoma yisiphi isikhathi. Ama-safety valve amabili axhunyiwe futhi anqanyuliwe ngesimo sokushintshana kwama-valve aseceleni.

I-Safety Relief Valve Group ifakwe i-pressure gauge yokuhlola ingcindezi yesistimu yamapayipi nganoma yisiphi isikhathi.

I-Safety Relief Valve Group inikezwe i-valve yokukhipha umoya. Ingasetshenziswa ukukhipha umoya epayipini lapho ihlanzwa, kanti i-nitrogen ingakhishwa lapho uhlelo lwe-nitrogen oluwuketshezi lusebenza.

Imishini ye-HL Cryogenic

I-HL Cryogenic Equipment eyasungulwa ngo-1992 iwuphawu oluhambisana neChengdu Holy Cryogenic Equipment Company eShayina. I-HL Cryogenic Equipment izibophezele ekwakhiweni nasekukhiqizweni kwe-High Vacuum Insulated Cryogenic Piping System kanye ne-Support Equipment ehlobene nayo.

Ezweni lanamuhla elishintsha ngokushesha, ukuhlinzeka ngobuchwepheshe obuthuthukisiwe ngenkathi kukhulisa ukonga izindleko kumakhasimende kuwumsebenzi onzima. Sekuyiminyaka engama-30, i-HL Cryogenic Equipment Company cishe kuzo zonke izinsizakusebenza ze-cryogenic kanye nezimboni igxile kakhulu endaweni yokusebenza, iqoqe ulwazi olucebile noluthembekile, futhi ihlola njalo futhi ilwela ukuhambisana nentuthuko yakamuva kuzo zonke izindlela zokuphila, ihlinzeka amakhasimende ngezixazululo ezintsha, ezisebenzayo nezisebenzayo, yenze amakhasimende ethu ancintisane kakhulu emakethe.

For more information, please visit the official website www.hlcryo.com, or email to info@cdholy.com .

Isikhathi sokuthunyelwe: Agasti-25-2021